About Us

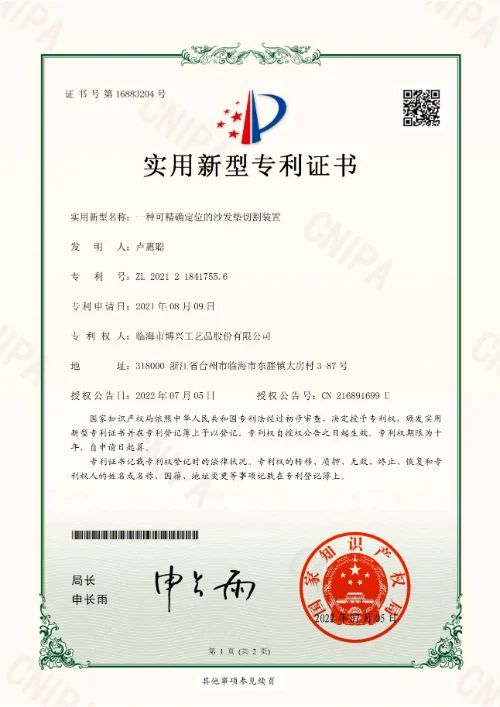

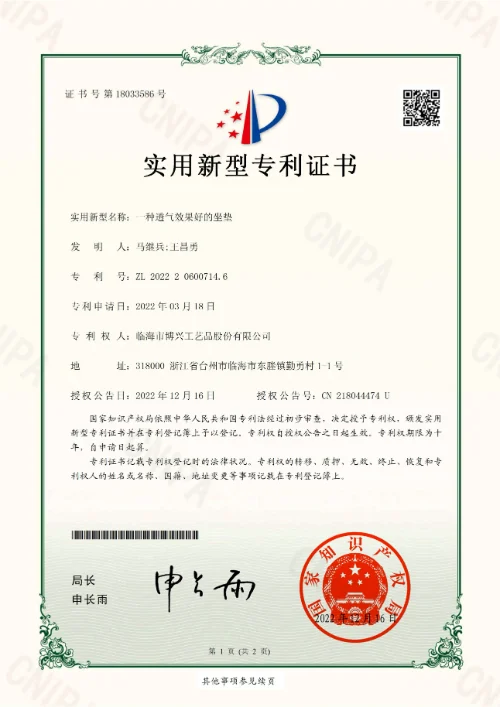

Commitment to Quality and Global Standards

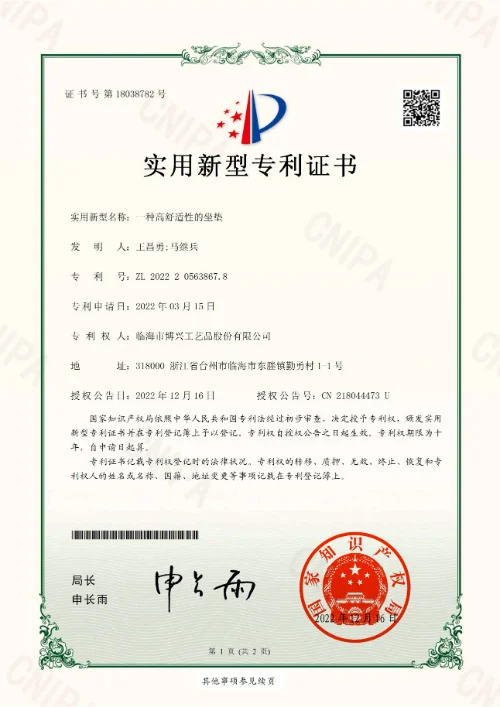

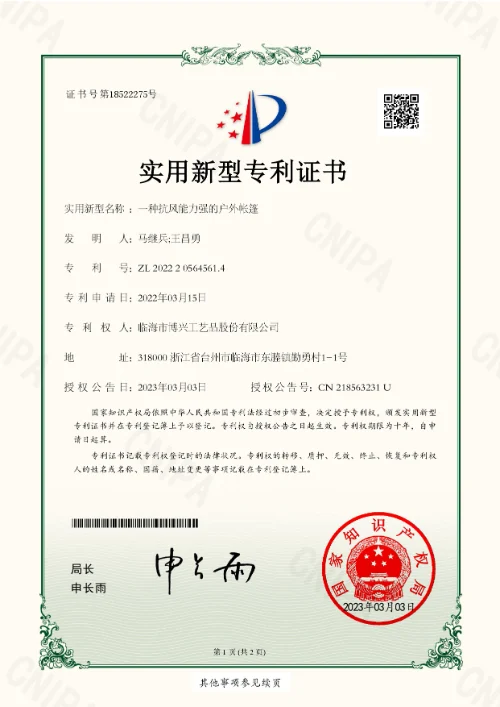

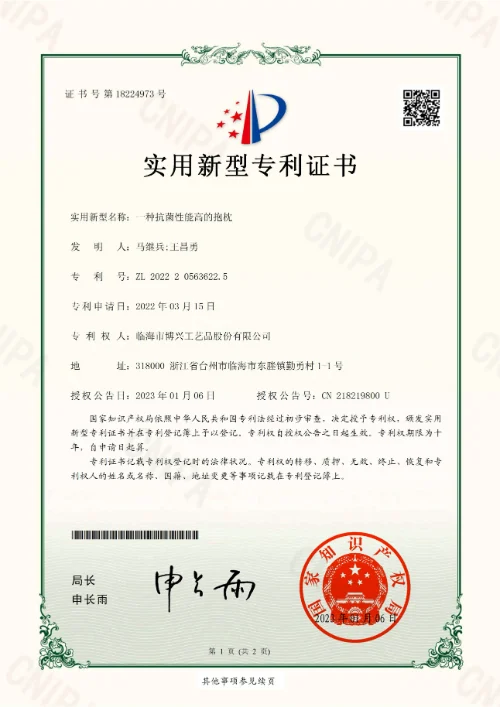

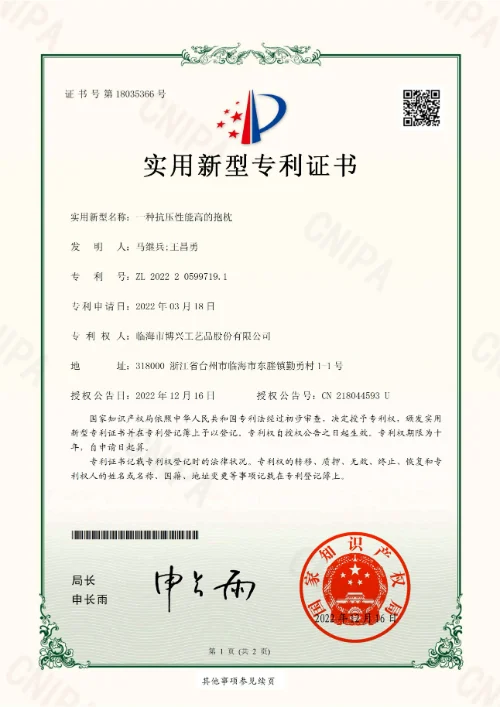

At Boxing, quality is at the heart of everything we do. We have implemented a rigorous quality control system where experienced technicians, QC staff, and skilled workers collaborate to ensure every product meets the highest standards. Our certifications — SEDEX, BSCI, GRS, and ISO9001 — reflect our commitment to ethical, sustainable, and high-quality manufacturing.

Thanks to the trust of our global customers and partners, our annual turnover has exceeded 16 million USD. We are continuously investing in upgrading our equipment and processes to maintain our competitive edge. By combining craftsmanship, innovation, and reliability, Boxing is dedicated to helping customers deliver exceptional outdoor experiences.

Our Production Process: From Concept to Completion

Cutting Workshop

Equipped with advanced CNC cutting machines, automatic fabric spreading machines, and professional cutting tools, the workshop efficiently handles various outdoor specific fabrics and ensure consistent cutting accuracy.Before cutting, all incoming fabrics undergo strict pre-inspection: workers check for surface defects, confirm fabric thickness and texture consistency, and align patterns (if applicable) to meet outdoor cushion aesthetic and functional requirements.

During the spreading process, the automatic spreading machine ensures even fabric layering without wrinkling, which is crucial for maintaining uniform size of products.

The workshop operates with a strict quality control system: dedicated QC inspectors randomly check cut pieces’ dimensions, edge smoothness, and fabric integrity after cutting. Additionally, all equipment is regularly calibrated and maintained to avoid deviations caused by mechanical wear, ensuring stable production efficiency.

Sewing Workshop

Equipped with a comprehensive range of industrial sewing machines — including high-speed lockstitch machines for basic stitching, overlock machines for neat edge finishing, and computer-controlled sewing machines for complex patterns or heavy-duty fabrics — the workshop ensures efficiency and precision in handling various outdoor fabrics. Additionally, auxiliary equipment like automatic zipper feeders, CAD machines, and edge-binding machines further enhances production consistency.

When sewing outdoor cushions, special attention is given to fabric properties and durability requirements. Sewing operators use waterproof polyester threads and adjust stitch density (typically 7–8 stitches per inch for optimal strength) to prevent water penetration at seams.

A rigorous quality control system is in place throughout the sewing process. Dedicated QC inspectors check each semi-finished and finished product for: uniform stitch formation (no skipped stitches or loose threads), seam strength and smoothness, proper installation of accessories (e.g., zippers that glide smoothly, buttons that fasten securely), and overall dimensional accuracy and appearance. Any defects are immediately identified and rectified to ensure only qualified products proceed to the next stage.

Filling & Compression Workshop

Equipped with specialized filling equipment tailored to outdoor cushion needs, the workshop efficiently handles a range of outdoor-grade fillings. This includes semi-automatic foam filling machines, fiber filling machines and digital weighing scales.

A rigorous quality control (QC) process runs throughout the filling stage. Dedicated inspectors conduct three key checks:

Filling consistency: Press each filled cushion to verify uniform support and confirm weight matches the design standard.

Seal integrity: Tug test the filling opening to ensure it withstands pulling.

Weather resistance compliance: Randomly sample filled cushions for water-repellent and anti-mildew tests.

Any cushions failing these checks are immediately reworked.

Packaging Workshop

Equipped with specialized packaging equipment tailored to the size, weight, and outdoor-specific protection needs of cushions, such as Semi-automatic stretch wrapping machines, Automatic weighing & labeling machines, Automatic packaging machine.

The packaging process is strictly standardized to adapt to outdoor cushions’ durability and logistics needs, following a step-by-step workflow (Pre-packaging Inspection, Tailored Packaging Selection, Labeling & Compliance and etc.).

A rigorous quality control (QC) process ensures packaging reliability(Protection Test, Seal & Moisture Check and Label Accuracy)

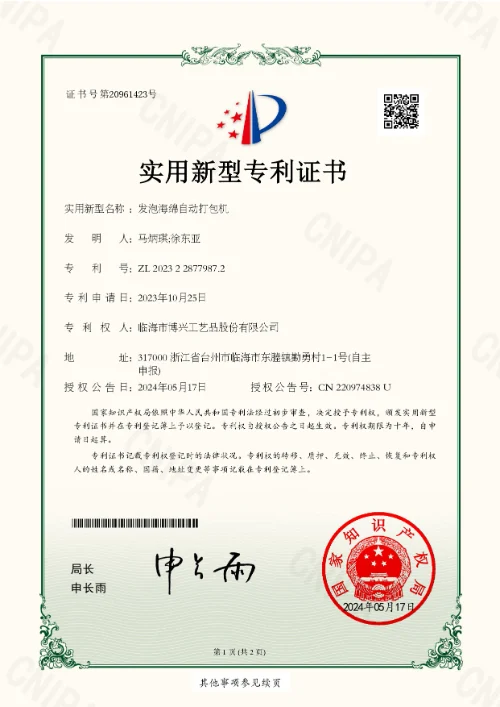

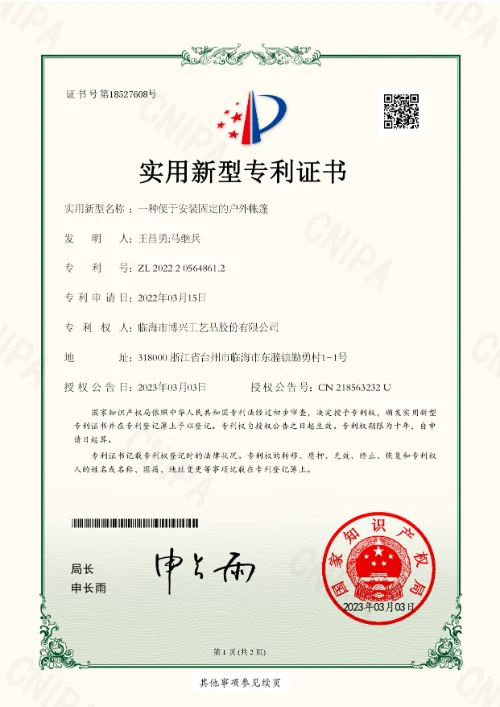

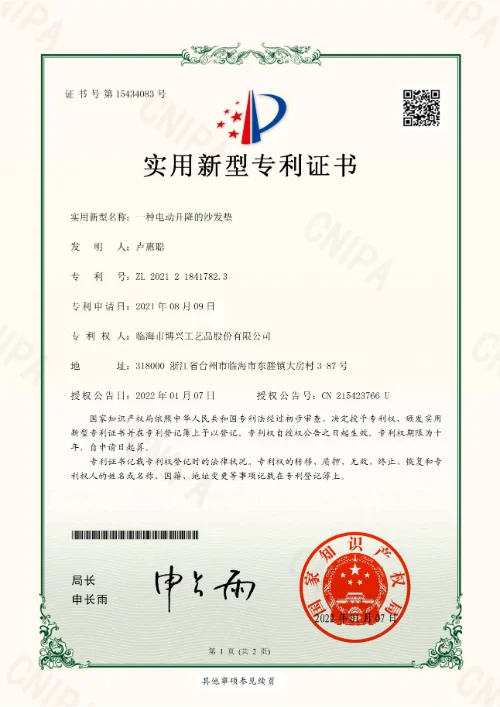

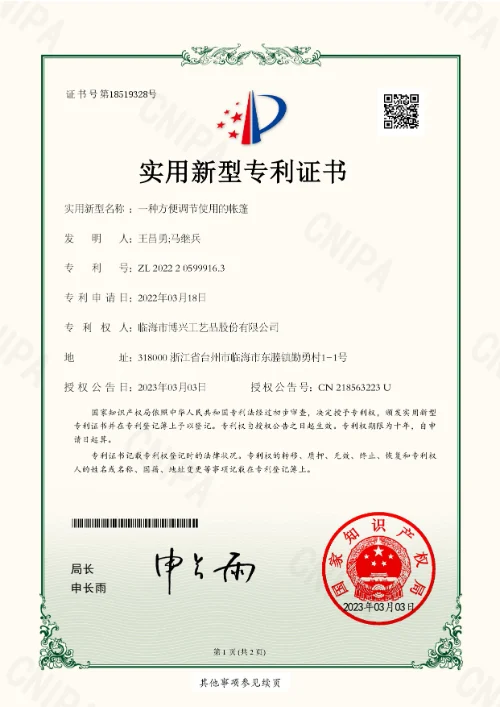

Trusted Quality, Proven by Standards